User manuals and manufacturer’s guidelines often have bolt patterns clearly spelled out. But on the off-chance that these instructions are inaccessible, no worries; this guide will describe how to measure rim bolt patterns in detailed steps.

Most people are concerned about the 5-lug bolt pattern – since it is the most popular hub design. Still, my one-size-fits-all guide can apply to other lug patterns as well; keep scrolling to learn why.

In this article:

How to Measure The Lug Bolt Pattern?

First, count the number of bolts (it should be a 4-, 5-, 6-, or 8-lug design). To calculate the diameter, measure the gap between two opposing bolt centers if you got 4, 6, or 8 lugs. For 5-lug patterns, assess the distance between a hole’s furthest outer edge and the 3rd bolt hole’s center.

A. Count The Number of Bolts

Step 1. Park your car and turn the engine off

The step is self-explanatory; no one wants the car to move amidst the measuring process! Hence, remember to park the car in an even, flat area, then engage its emergency brakes for added stability.

In the case of vehicles with no wheels (say, parts cars in junkyards or repair shops), use jack stands to secure them. Double-check their placement before moving on to the follow-up steps.

Step 2. Remove the tire’s hubcap with a screwdriver

Some vehicle wheels arrive with hub caps to protect and cover the wheel lugs.

Pick a screwdriver (preferably flat head) and slot it between the rim and the hubcap’s outer edge. Apply pressure gently to pry the hubcap off.

There is no need to pull off all four hubcaps from all four tires; since their bolt patterns are identical, removing just one hubcap is more than enough.

Note: Certain models allow drivers to inspect the nuts without hubcap removal. In that case, skip this step and go straight to the next one.

Step 3. Count all the pattern’s bolts.

At the wheel center is a large circle with rounded nuts that cover the bolts; their job is to ensure the wheel stays attached to the vehicle.

Count how many bolts with lugs that you can see. The most common options will be 4 or 5 lug nuts; 8-lug or 6-lug are also possible scenarios to consider.

Step 4. Keep the nuts exposed for further measurement

Do not return the hubcap to its place just yet; you would have to pull it off again anyway when we move on to the pattern’s diameter. Keep things the way they currently are; in the meantime, put the hubcap somewhere accessible/ easy to remember.

B. Find The Circle Diameter

Step 1. Measure the gap

As previously mentioned, 4-, 5-, 6-, and 8-bolt designs are arguably the most common. Once confirming the number of lug holes on your bolt wheels, choose a measuring method accordingly:

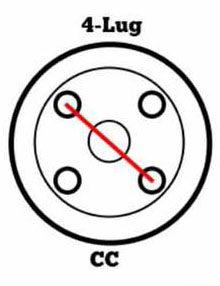

4-lug bolt pattern measurement:

Pick two holes that sit directly opposite each other. Then measure the straight-line gap between the centers of the two.

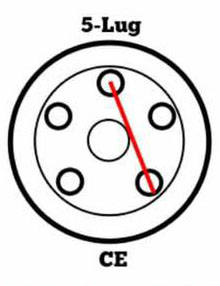

5 lug bolt pattern measurement:

5-lug patterns might be more challenging – since the holes aren’t at direct opposites this time. No wonder people with 5-lug wheel hubs tend to mess up their measurements more than others!

To measure 5 lug bolt pattern, use a gauge ruler or tape measure to assess the straight-line gap between a hole’s furthest outside edge and the 3rd bolt’s center.

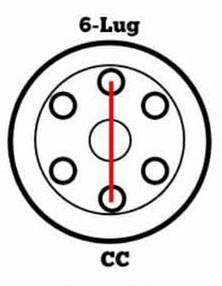

6 lug bolt pattern measurement:

Like with 4-lug patterns (both 4 and 6 are even numbers), measure the distance between a hole’s center to the center of another hole across from it.

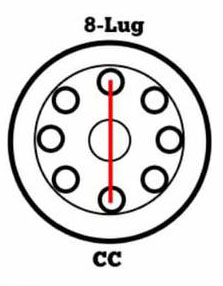

8 lug bolt pattern measurement:

Since 8 is also an even number, simply use the same tips for 4- and 6-lug designs.

Note: You may use bolt circle templates as an alternative.

For those seeking extremely accurate measurements, bolt circle templates are inexpensive and very user-friendly: all you need to do is to slide the circle templates over the wheel studs and check the size marking!

The tires do not have to be removed during the process; hence, jacking up the car will also be unnecessary.

Step 2. Combine the diameter and bolt number to get your measurements

Take the two numbers you just got and put an “X” between them, which is the exact bolt pattern you need. It can be in either millimeters or inches. For instance, 4 x 130 mm/ 4 x 5.1 means:

- The vehicle has four hub bolts

- Its diameter is 130 mm or 5.1 inches

C. Extra

Although the chances of the rear wheels and front wheels having different patterns are rare (hence our suggestion to remove only one hub cap), feel free to check both if you have suspicions.

No one knows what could have happened, especially when it comes to second-hand vehicles or aftermarket passenger car upgrades.

What Is The Most Common Bolt Pattern?

Five-lug bolt patterns have been the No.1 hub designs for years in terms of popularity, often found on all types of vehicles from standard to luxury. As such, finding aftermarket lug nuts or wheels for them is quite a breeze.

Below is the full measurement and conversion chart for five-lug wheel bolt patterns:

| Bolt pattern (inches) | Bolt pattern (mm) |

| 5 x 3.86 | 5 x 98 |

| 5 x 3.94 | 5 x 100 |

| 5 x 4.25 | 5 x 108 |

| 5 x 4.33 | 5 x 110 |

| 5 x 4.41 | 5 x 112 |

| 5 x 4.5 | 5 x 114.3 |

| 5 x 4.52 | 5 x 115 |

| 5 x 4.72 | 5 x 120 |

| 5 x 4.75 | 5 x 120.7 |

| 5 x 5 | 5 x 127 |

| 5 x 5.12 | 5 x 130 |

| 5 x 5.31 | 5 x 135 |

| 5 x 5.5 | 5 x 139.7 |

| 5 x 5.91 | 5 x 150 |

| 5 x 6.1 | 5 x 155 |

| 5 x 6.5 | 5 x 165.1 |

| 5 x 8.07 | 5 x 205 |

Can You Change Your Lug Bolt Pattern? How?

Lift the car off the ground and remove the nuts and wheels. Attach the adapter bolts to the trailer wheel hubs, tighten them (along with the studs), and send the car back to the ground. The process should not take more than two hours.

Step 1. Find out whether the market offers any suitable adapters for your conversion. If needed, have these adapters custom-made by trusted companies to ensure 100% success.

Step 2. Loosen the lugs (do not remove them yet) and lift the car off the ground with a jack. Lower it on a jack stand, then completely pull out the lug nuts and wheels.

Step 3. Attach the adapter’s supplied bolts to the hubs and tighten them according to the specified torque specs. Make sure the studs do not extend above the adapters; if that is the case, use shorter studs.

Step 4. Mount your wheels onto the studs, tighten the nuts, and return the car to the ground.

What Are Dual-Drill Bolt Patterns?

As the term “dual” suggests, dual-drill bolts arrive with an extra lug hole set, which enables it to work with two different bolt patterns.

Take a 5 x 114.3/5 x 100 pattern, for example; it has ten holes in total, fitting both 5 x 114.3 and 5 x 100.

Conclusion

Measuring bolt pattern on 5 lug wheels (odd number) is slightly different from 4-, 6-, and 8-bolt patterns (even numbers), but it shouldn’t challenge even a novice. Keep in mind my detailed guidelines above to sidestep miscalculations, and write to me for more support if needed.