More often than not, drivers do not spend much time contemplating wheel types during their purchase, assuming that all of them look and function the same. That could not stray further from the truth, which motivates my team to craft these insightful guidelines and debunk the common myths.

Each style of rims and wheels arrives with respective design features, benefits, and functioning mechanisms. Keep scrolling for more.

In this article:

What Are The Common Types of Wheels? A Comprehensive Overview

Seven wheel types have been brought to the market so far, with varying degrees regarding strength, integrity, and power.

Steel Wheels

Also referred to as Steelies, steel wheels are the standard wheel type in our global automobile industry, manufactured via steel billet pressurization and powerful hydraulic machines.

Low-end cars have employed them for decades, keeping these tires dominant in the wheel market – until alloy rims started to gain momentum due to lighter designs and more affordable pricing.

At a closer look, steels are alloys of iron and carbon, rendering them harder and stronger than most manufacturer materials. Unfortunately, that comes at a price: steelies are heavier and bulkier than average as a result, posing numerous portability difficulties in emergencies.

The stringent manufacturing process also leaves little room for graphic or new designs – a drawback most aesthetic fans would not appreciate. To conceal its somewhat hideous look, automobile companies use hubcaps (with badging) and give its overall outlook a more stylish touch.

Alloy Wheels

Stealing the thunder of steel wheels to become the most popular wheel type in today’s cars, alloy wheels are a force to be reckoned with.

They are produced using magnesium and aluminum alloys (that explains why steelies are not considered alloy wheels, despite containing some alloy themselves).

From a more critical look, it is not difficult to figure out the reason behind the rise of alloy wheels:

- Their strength is better than steelies; the latter is more pliable and much softer.

- Alloys are lighter-weight while still offering similar (or even better) performance.

- The heat-conducting ability is top-notch, paving the way for greater visual appeals than steel wheels.

With their current popularity, few know that back in earlier days, alloy wheels used to comprise magnesium only; it was the ductility issues that encouraged brands and manufacturers to implement more innovations.

After thousands of experiments and cast refinements, aluminum is added to the mix to replace pure-magnesium wheels, delivering high performance and speed at a relatively low cost.

And that paves the way for premium wheels to roll out, made of aluminum alloys with a chrome/enamel coating.

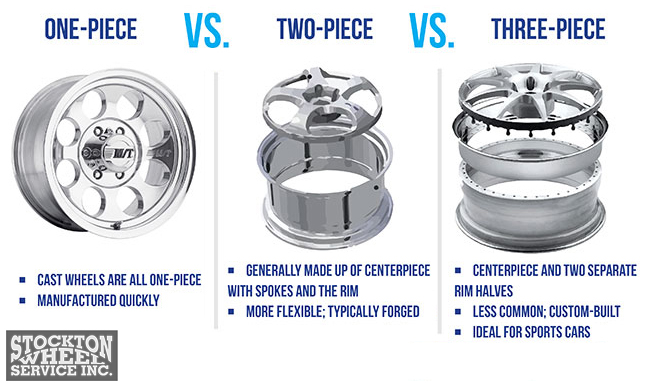

Multi-piece Wheels

Introduced to the market by BBS, multi-piece wheels can be made using 2 or 3 components, as their name suggests.

- Two-piece: The 2-piece versions are constructed with rim and wheel faces, bound together by rim screws across the center’s circumference. Once done, manufacturers apply sealants to them, securing the sections and fittings together.

- Three-piece: Compared to two-piece wheels, three-piece wheels offer more adjustability and freedom for the width, as the rims can be broken down into two segments.

With all these complex and intricate layouts, don’t be surprised that multi-piece wheels used to feel much weaker or heavier than single-piece. Hence, BBS has launched a “rolling rim” technology, aiming to help build multi-piece of equivalent strength to single piece.

Chrome Wheels

Most cheap-pricing wheels arrive with painted coatings to sidestep corrosion. Sure, some do not need painting – but only when the rim materials themselves are corrosion-resistant.

As painted coats are messy and leave unsightly streaks on the tires, people with more generous budgets turn to wheels with chromium layers instead.

Better corrosion resistance aside, their visual appeal is also amazing, giving the car a more eye-catching, fashionable, and shiny look. I strongly suggest turning to chrome-coating wheels if you love to show off your cars to acquaintances and fellow drivers.

Diamond-Cut Wheels

Diamond-cut versions are quite similar to standard alloy wheels – except for their higher-sine, diamond-y finish. More specifically, automobile manufacturers create a metal incision with machine lathes, delivering a shiny impression on the edges and some grooving effects.

These luxurious wheels are undoubtedly a remarkable contributor to the car’s aesthetic and appealing layout. As such, you will often see them in vehicle upgrades and refinement – along with the chrome wheels discussed above.

Varied personalization choices are another benefit that keen automobile enthusiasts should not skim over. They are available in numerous color themes, including gunmetal gray, vibrant orange, etc.

Forged and Cast Wheels

For those seeking aftermarket wheels for their cars, there are usually only two wheel types to consider – cast and forged – though not many differences are detected in their designs. The only major variation lies in their manufacturing procedures.

More specifically, brands produce forged wheels by – you guessed it – forging one solid aluminum piece into the rim’s shape. Meanwhile, for cast wheels, producers usually pour aluminum (liquified beforehand) into molds.

In most cases, forged wheels are everyone’s favorite, 25% lighter and three times stronger than their cast counterparts – a feature every racing driver would love to include for their cars.

Unfortunately, nothing good comes cheap; forged wheels demand thrice as much as cast wheels.

To save cost, people must thoroughly scour the market for rare cast wheels cheaper and lighter than forged ones. One such example is the Enkei RPFI: with a measurement of 18×9.5 at merely 17.9 pounds, its performance is comparable to some of the most common forged wheels.

OEM Style (Replica) Wheels

If you drop by automobile forums and markets often, thousands of advertisements on “high-quality, premium replicas” of varied car brands must have been plaguing you on a daily basis. But it would be best to stay far from them, no matter how tempting these offers might be.

Although the designs and outlooks of the replicas might look identical to OEM ones, they lag far behind regarding strengths and essential features.

Honestly, that is to be expected, since the replica wheels must be made at low manufacturing costs, and hence, sacrificing quality as a result.

More specifically, the method used is called “gravity casting”: after pouring the molten metals into the mold, manufacturers do nothing to compress them and leave the rest of the hard work to… gravity.

Needless to say, that is a stark contrast to OEM wheels, manufactured via intense compression force. No wonder the replicas always feel weak and brittle, and even pose potential risks to the vehicle’s occupants.

What Are The Different Types of Rims?

As rims are a critical element of the entire wheels, seasoned drivers might also take an interest in learning their different categories.

Safety Rims

Safety steel rim and passenger vehicles often go hand in hand, with inward-extending bumps that keep the beads off the outer edge but closer to the rims.

Tire pressure plays a huge part in assisting these pumps, which explains why they will likely malfunction if your tires are not properly inflated.

Split Rims

Heavy vehicles (such as heavy-duty trucks, forklifts, or tractors) occasionally use multi-piece rims with side or lock rings to keep the tires in place.

While their benefits are undeniable, split rims and multi-piece wheels might bring significant dangers when suddenly separated. Worse, there might even be explosions. As a result, these rims and wheels are almost always absent on regular or passenger vehicles.

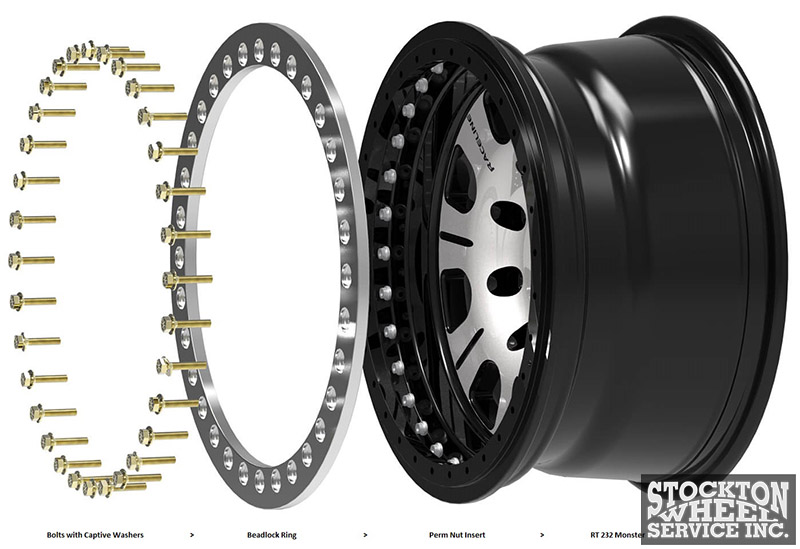

Beadlock Rims

Arguably the most distinctive one of the bunch, beadlock rims mostly aim at off-roading driving. More specifically, they clamp the rim to the bead physically via non-pressure connections, preventing the risks of tires falling apart.

While certain bead locks are DOT-compliant, most are not considered legal for regular road use. Their extra bulkiness only adds to the inconvenience, so the chances of seeing beadlock rims on normal streets are pretty unlikely.

What Wheel Type Should You Choose For Your Car?

As briefly mentioned above, turn to steel or aluminum wheels for regular driving and budget-saving performance.

For those looking for longer shelf life with a lighter profile in the aftermarket, forged wheels are the best choice. Meanwhile, drivers prioritizing aesthetic and luxurious finishes should aim for chrome or diamond cut.

But I must say forded ones are geared towards race cars more than daily passenger cars. I used to install a set of Volk CE28N flow-formed wheels on my SUV, but it threw me a lot of stress worrying that I would hit a curb, crack/bend the rim, and end up with an expensive repair.

Assess your needs to land the most suitable alternative.

Do Wheels/Rims and Tires Have to Match?

Yes. The wheels and rims are comparable to a pair of running shoes. How can you ace hundreds of miles to get to the finish line if the shoes do not even fit your toes?

Keep driving on mismatched wheels and tires will wear the latter down unevenly, causing collisions and blowouts during the trip.

Conclusion

I hope this detailed breakdown can address your current concerns and questions regarding the available wheel options. As you can see, not all of them are tailored to your performance or aesthetic needs, so weigh the pros and cons carefully. Write to me if you want more help.